Building the Modern House - an owners tale by Dan Akst

Daniel Akst is an author and journalist who has written several articles covering the recent prefab and Re-Modern movement. His articles have appeared in the Wall Street Journal, New York Times and he's even written about modern homes for This Old House. Most significantly he has built his own modern house and written extensively about it. These are a worthwhile read for anybody building their own modern home. Dan first offered up his story in a three part article that appeared in Money Magazine. You can read the text of these articles on his own web site here: Part 1 Part 2 Part 3 He also wrote a shorter account with more of a design emphasis for Metropolis Magazine that you can read at the on their web site: link. Its interesting that at the end of this article Dan calls for the production of decent house plans for modern homes: ...If they did, they might want to use a stock plan; but here is another reason why more interesting houses don't get built, even by individuals who care about good design. Most of the house plans sold through books and on the Internet are awful; a few decent ones are available (including some in the Life magazine's "Dream House" series) but virtually none are Modern, unless what you really want is a chunky-looking "contemporary" with diagonal wood siding. The absence of good Modern stock plans means that people who want this kind of house have to hire an architect, at fees ranging from a few thousand dollars to perhaps 15 percent of the construction cost. Although Modern architecture remains suffused with the rhetoric of idealism, even relatively prosperous families who are thinking of sponsoring it will beg off unless the entire clanking apparatus of home-ownership--all of it geared to the lowest common denominator of design--can be brought around to accommodate something more interesting. Modular housing might be one answer. Another would be the publication of some first-class stock plans that specify standard materials to achieve quietly fabulous results. Incredibly this is just what we have set out to do, and our customers have in fact done. Dan's article was in the November 2002 issue of Metropolis. Our plan site went live on November 4th, 2002. He's also a good novelist - I've read a couple of his books and enjoyed them. More info about the rest of his work on his web site Akst.com.

Technorati Tags: modern design, modern house

Continue reading "Building the Modern House - an owners tale by Dan Akst"

Click through below to continue reading..

Click through below to continue reading..

But the majority of prefab in the USA is in the form of modular construction. Modular construction reduces the field connections to a a few major utility connections when the boxes are placed on the foundation, but otherwise are much more complete when they arrive at the site. Granted, this is not the reason why modular is more popular in the US. Modular housing here grew out of motor-home construction, which was a more permanent version of a trailer. When the flimsy construction of motor-homes became an obvious problem in the US it was put under a nation wide spec known as a HUD Code. At that point the industry split into factories that continued to build motor homes under the new rules, and factories that adapted to building to local site built construction codes which became the modular industry. That has dominated the US prefab business ever since. Its popularity here is due to administration - not because it makes construction sense. And how could it make construction sense? Shipping a house in big pieces is tantamount to shipping air. There is a reason why Ikea ships furniture in a flat-pack. The shipping is so much more efficient for flat goods, than big boxy hollow goods. The challenge becomes how to complete as much of the house as possible while still being able to ship it flat. Whole houses arrive on two trucks rather than 4 or 5.

Next we'll get into more detail about how these houses go together.

Previously:

But the majority of prefab in the USA is in the form of modular construction. Modular construction reduces the field connections to a a few major utility connections when the boxes are placed on the foundation, but otherwise are much more complete when they arrive at the site. Granted, this is not the reason why modular is more popular in the US. Modular housing here grew out of motor-home construction, which was a more permanent version of a trailer. When the flimsy construction of motor-homes became an obvious problem in the US it was put under a nation wide spec known as a HUD Code. At that point the industry split into factories that continued to build motor homes under the new rules, and factories that adapted to building to local site built construction codes which became the modular industry. That has dominated the US prefab business ever since. Its popularity here is due to administration - not because it makes construction sense. And how could it make construction sense? Shipping a house in big pieces is tantamount to shipping air. There is a reason why Ikea ships furniture in a flat-pack. The shipping is so much more efficient for flat goods, than big boxy hollow goods. The challenge becomes how to complete as much of the house as possible while still being able to ship it flat. Whole houses arrive on two trucks rather than 4 or 5.

Next we'll get into more detail about how these houses go together.

Previously:

images from the

images from the  What a beautiful scene! Look at that sky. There are a couple more high res shots from this day in the

What a beautiful scene! Look at that sky. There are a couple more high res shots from this day in the

Here is the corner of the house next to the carport. Yup, that's a

Here is the corner of the house next to the carport. Yup, that's a  A great fish-eye view of the overlook to the living spaces from the hallway above.

A great fish-eye view of the overlook to the living spaces from the hallway above.

The owner has explained some of the changes to me in their email. They have made the bathroom slightly larger with space taken from the master bedroom. This will even out the size of the two bedrooms which for them is fine as their masterbedroom will be in the adjacent

The owner has explained some of the changes to me in their email. They have made the bathroom slightly larger with space taken from the master bedroom. This will even out the size of the two bedrooms which for them is fine as their masterbedroom will be in the adjacent  You can also see at the top of the wall the sloping top plate which will allow them to gather all the rainwater at one side of the house. They say the work on the Plat House will also begin very soon, and I'll have to come up with a new title for this project!

You can also see at the top of the wall the sloping top plate which will allow them to gather all the rainwater at one side of the house. They say the work on the Plat House will also begin very soon, and I'll have to come up with a new title for this project!

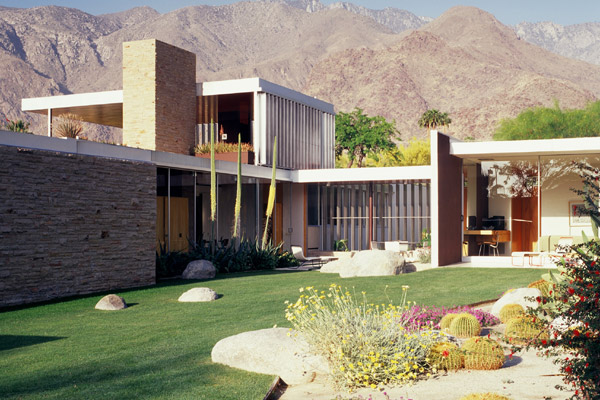

the Kaufmann House designed by Richard Neutra, 1946, photo by Tim Street-Porter for the New York Times

the Kaufmann House designed by Richard Neutra, 1946, photo by Tim Street-Porter for the New York Times

Of course that notion is preposterous. It is a great benefit to be able to see that somebody else has built a given house, and that there is a photo record of construction images that you can access with your builder. It can help remove any uncertainty they may feel if they are faced with building a house that they may consider unusual. But this is an anomaly in an architects practice, that a design would be built repeatedly. Any architect must be capable of designing and documenting a house or building that has never been built before, no second chances, it must come together from the plans on the first try. They have to do that every day, as assuredly as you get up every morning, if they hope to be in business the next day. The vast majority of architects I know are very good at that.

Of course that notion is preposterous. It is a great benefit to be able to see that somebody else has built a given house, and that there is a photo record of construction images that you can access with your builder. It can help remove any uncertainty they may feel if they are faced with building a house that they may consider unusual. But this is an anomaly in an architects practice, that a design would be built repeatedly. Any architect must be capable of designing and documenting a house or building that has never been built before, no second chances, it must come together from the plans on the first try. They have to do that every day, as assuredly as you get up every morning, if they hope to be in business the next day. The vast majority of architects I know are very good at that.

With that in mind I'd like to report that the

With that in mind I'd like to report that the

The owner is taking a series of fantastic panoramic photos which give you an expansive view of the framing - really the next best thing to being there. They are posted to

The owner is taking a series of fantastic panoramic photos which give you an expansive view of the framing - really the next best thing to being there. They are posted to  A great view of the back of the house - it really looks like a

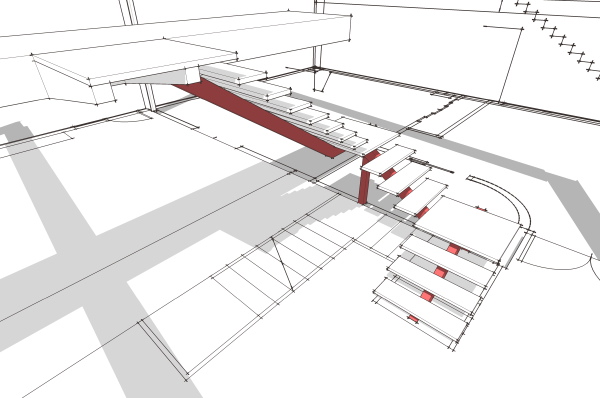

A great view of the back of the house - it really looks like a  The stair consists of a single steel stringer with cantilevered treads and risers. Not a completely unusual configuration, but not as often configured in a U shaped stair. The undercarriage was all exposed and visible, so we did not want to see a post coming down to the floor under the landings. So our posts are actually hidden in the adjacent wall which you can still see here as the wall framing has not received drywall yet.

The floor to floor height is high, so the stair needed to be quite long. And we could not have the bottom of the stair crowding the front door. So it found itself pushed back and leading up to a cantilevered landing which hangs off the second floor bridge. The steel work for this landing, and the undercarriage of the stair is all hanging out for view and it has really become a microcosm for the construction of the house - a place where you can get right up to the connections and lay your hands on them compared to the roof and floor beams that are high above your head.

The stair consists of a single steel stringer with cantilevered treads and risers. Not a completely unusual configuration, but not as often configured in a U shaped stair. The undercarriage was all exposed and visible, so we did not want to see a post coming down to the floor under the landings. So our posts are actually hidden in the adjacent wall which you can still see here as the wall framing has not received drywall yet.

The floor to floor height is high, so the stair needed to be quite long. And we could not have the bottom of the stair crowding the front door. So it found itself pushed back and leading up to a cantilevered landing which hangs off the second floor bridge. The steel work for this landing, and the undercarriage of the stair is all hanging out for view and it has really become a microcosm for the construction of the house - a place where you can get right up to the connections and lay your hands on them compared to the roof and floor beams that are high above your head.

More photos after the fold.

More photos after the fold.

The site looks beautiful and we are really looking forward to seeing the house come together. Remember all the photos of this project will be

The site looks beautiful and we are really looking forward to seeing the house come together. Remember all the photos of this project will be

and the latest from the site after the jump:

and the latest from the site after the jump:

The SIPs panels had to be transferred from the semi truck that delivered them to a smaller flat-bed in order to manage the drive up to the site. The smaller truck was the type with the lift boom built in which was convenient for loading and unloading. Once on the site SIPs panels go up rapidly.

The SIPs panels had to be transferred from the semi truck that delivered them to a smaller flat-bed in order to manage the drive up to the site. The smaller truck was the type with the lift boom built in which was convenient for loading and unloading. Once on the site SIPs panels go up rapidly.

There are several modifications that the owners and developer have worked out themselves and with the SIPs manufacturer. The house includes a garage which is on the bunk room end of the house as at this site you approach the house from that end. Other changes are to the windows, some out of the owners desires, and others apparently out of the use of SIPs. In order to "float" a window opening within a panel there needs to be some margin of panel all around the window. Many of the Plat House windows run right into the corners which may be very difficult to do with the SIPs panels. It is interesting in the photos to see how they are joining the post and beam framing of the window wall side into the SIPs panels.

There are several modifications that the owners and developer have worked out themselves and with the SIPs manufacturer. The house includes a garage which is on the bunk room end of the house as at this site you approach the house from that end. Other changes are to the windows, some out of the owners desires, and others apparently out of the use of SIPs. In order to "float" a window opening within a panel there needs to be some margin of panel all around the window. Many of the Plat House windows run right into the corners which may be very difficult to do with the SIPs panels. It is interesting in the photos to see how they are joining the post and beam framing of the window wall side into the SIPs panels.

More images after the jump.

More images after the jump.

The owner has been shooting a series of panoramic photos that he is stitching together from individual shots. Check them out in the slide show below - its worth clicking through to Flickr to look at them full size.

The owner has been shooting a series of panoramic photos that he is stitching together from individual shots. Check them out in the slide show below - its worth clicking through to Flickr to look at them full size.

Here is a close up of the floor trusses that were used for the second floor. These are great because they make it so much easier to run pipes and ducts. Its not as necessary for the first floor if you are over a crawlspace, but if you want a finished basement they are also good for saving your headroom from duct soffits. And for the second floor they are ideal. More photos after the jump.

Here is a close up of the floor trusses that were used for the second floor. These are great because they make it so much easier to run pipes and ducts. Its not as necessary for the first floor if you are over a crawlspace, but if you want a finished basement they are also good for saving your headroom from duct soffits. And for the second floor they are ideal. More photos after the jump.

There is still not power at the site, so the scope is not up and running yet. I'm sure we will see some photos from it as soon as its powered up and calibrated to the control software and dome. In the Flickr photo stream below you can see photos of the scope arriving and being installed. The telescope is manufactured by

There is still not power at the site, so the scope is not up and running yet. I'm sure we will see some photos from it as soon as its powered up and calibrated to the control software and dome. In the Flickr photo stream below you can see photos of the scope arriving and being installed. The telescope is manufactured by  There is is, looking much like our

There is is, looking much like our  Long time readers of the

Long time readers of the  When David began these efforts they were an offshoot of the work he was doing in container modification for the Tampa Armature Works, or TAW. A large vendor in remote site power generation, and associated shelters David's container expertise was being put to work for them in their main business. At the same time they were supportive of his pursuit of housing and building with the containers as a way to expand this part of their business. Eventually however they parted ways as David set out to concentrate on this 100%. Joining him were business partners that had previously provided engineering and logistics expertise in the container mods that he had done before - SG Blocks was born.

One of these partners is Steve Armstrong, a structural engineer who has over the years provided David with consultation on container mods, and was in from day one on David's efforts to create housing. While David was on his journey Steve was on his own. During this span of time Steve went to work for a large senior housing developer, Stratford, and while he was there he continued to consult to David. Enter Bruce Russell and Paul Gavin who were with Stratord and watching the work that David and Steve were doing. This group formed the foundation of SG Blocks which was completed with a relationship with ConGlobal, an nationwide container handler who provides the raw material at sites all across the country. These multiple depot sites double as fabrication sites allowing them to cover the entire country, and reduce shipping distances.

When David began these efforts they were an offshoot of the work he was doing in container modification for the Tampa Armature Works, or TAW. A large vendor in remote site power generation, and associated shelters David's container expertise was being put to work for them in their main business. At the same time they were supportive of his pursuit of housing and building with the containers as a way to expand this part of their business. Eventually however they parted ways as David set out to concentrate on this 100%. Joining him were business partners that had previously provided engineering and logistics expertise in the container mods that he had done before - SG Blocks was born.

One of these partners is Steve Armstrong, a structural engineer who has over the years provided David with consultation on container mods, and was in from day one on David's efforts to create housing. While David was on his journey Steve was on his own. During this span of time Steve went to work for a large senior housing developer, Stratford, and while he was there he continued to consult to David. Enter Bruce Russell and Paul Gavin who were with Stratord and watching the work that David and Steve were doing. This group formed the foundation of SG Blocks which was completed with a relationship with ConGlobal, an nationwide container handler who provides the raw material at sites all across the country. These multiple depot sites double as fabrication sites allowing them to cover the entire country, and reduce shipping distances.

So in one way or another the partners of this group have had a hand in many of the container projects you have seen on the internet, and they have been providing technical back up for me as I've worked up my the design of my proposed system. They have the technical know how to see projects through to completion including the backup that may be required for a rigorous permitting environment.

So in one way or another the partners of this group have had a hand in many of the container projects you have seen on the internet, and they have been providing technical back up for me as I've worked up my the design of my proposed system. They have the technical know how to see projects through to completion including the backup that may be required for a rigorous permitting environment.

Here is a link to their site:

Here is a link to their site:

The owners have a great site nestled among a stand of live oaks and cedars. They are building the Porch House right between several of the trees which I think really reinforces that connection between the inside and outside. In the photos we can see their footing piers in process. The long footings in the center lie below the stair which should give you some orientation to the floor plan.

The owners have a great site nestled among a stand of live oaks and cedars. They are building the Porch House right between several of the trees which I think really reinforces that connection between the inside and outside. In the photos we can see their footing piers in process. The long footings in the center lie below the stair which should give you some orientation to the floor plan.

The owners are going to be using some interesting green tech in the house. They are planning on a composting toilet, and a small septic system that will deal only with grey water from the sinks and kitchen. They are also going to be collecting rainwater, and they have plans to modify the roof slope to simplify the collection of the run off on one side of the house. We'll have to watch and see how that plays out.

The owners are going to be using some interesting green tech in the house. They are planning on a composting toilet, and a small septic system that will deal only with grey water from the sinks and kitchen. They are also going to be collecting rainwater, and they have plans to modify the roof slope to simplify the collection of the run off on one side of the house. We'll have to watch and see how that plays out.

Their long range plan is to add a

Their long range plan is to add a  And from the front we can see the large window in the living room and the recess at the front porch and entry. The horizontal windows at the kitchen, and the taller window from the mud room at the far end, with the garage beyond.

And from the front we can see the large window in the living room and the recess at the front porch and entry. The horizontal windows at the kitchen, and the taller window from the mud room at the far end, with the garage beyond.

Here we can see the joining of the slab on grade at the front of the house with the basement construction at the rear, as their floor joists are just going in. Looking to the left you can see the kitchen which is open to the living spaces which will be over the basement, and the laundry and rest room that are between the kitchen and the entry to the house.

Here we can see the joining of the slab on grade at the front of the house with the basement construction at the rear, as their floor joists are just going in. Looking to the left you can see the kitchen which is open to the living spaces which will be over the basement, and the laundry and rest room that are between the kitchen and the entry to the house.

The setting for the house looks great and they will enjoy a nice view of the woods out of the back of the house from all the living spaces. I'm sure the second floor framing will follow soon so keep watching. Remember, you can also follow the construction with all of the owner's photos at

The setting for the house looks great and they will enjoy a nice view of the woods out of the back of the house from all the living spaces. I'm sure the second floor framing will follow soon so keep watching. Remember, you can also follow the construction with all of the owner's photos at