Huh? What kind of question is that? When was there ever any "good vinyl siding"? Well that's the point. There wasn't ever any.

It's easy to knock vinyl siding. I doubt many people reading these words here really like vinyl siding very much. When its mentioned here its most often in derision or as a way to describe the mediocrity of mainstream house building practices. I don't want to simply "pile-on" a product that is scorned in our modern community. I really want to try and make sense out of it. Why has an industry as big as the home building materials industry singularly failed to make a decent vinyl siding product?

On the face of it, vinyl siding sounds like a good idea. Here we have a cladding product that has integral color, does not need to painted, it is light weight and easy to install with average skill sets. It is relatively inexpensive and widely available. A do-it-yourselfer can tackle it without fear and achieve results comparable to a pro. It is durable and resilient, and easily repaired(replaced) if damaged. As a plastic product it fulfills much of the mid-century promise of a future made easier through technology. What is wrong with that?

What is wrong with vinyl siding? Well first off the plastic that it is made of is part of the problem. Its been well documented elsewhere why the vinyl compounds in vinyl siding are bad, so I'm not going to get into here. Spend some time on Google and find out for yourself. Its nasty stuff. But beyond the open ended chemistry experiment we've unleashed on ourselves with vinyl siding there is the matter of the design of the siding panels themselves. Of course they have been conceived as an imitation of actual wood siding panel. The profiles of traditional lap siding panels have been copied, rendered now in saggy thin vinyl sheet. A fair wind will get the panels vibrating against themselves making that slappy sound of thin plastic sheets. From a distance it appears somewhat all right, as long as you don't catch a view of the side lapped seams which expose the fallacy. But to approach it and lay hands on it is to destroy any illusion of what it is. There is no substance there, at least when the expectation of solid wood has been proposed. Even at this close range there is the attempt to deceive us. All manner of false texture has been attempted, from cartoon quality wood grain, to reasonably convincing paint strokes. The problem is that from the start the proposition is that wood is what we would like to be and though plastic is what we obviously are it simply is not good enough, never would be satisfactory to be, never would it be adequate to be just plastic. I think Woody Allen said it best: Vinyl siding would never want to be a member of a club that had somebody like itself for a member... (correction: Lloyd Alter points out that this saying originates with Groucho Marx, Woody quoted him in Annie Hall, thanks Lloyd.)

Why oh why can't somebody make a vinyl siding panel that would be happy to just be what it is - plastic? Would that be so bad? Saturn can make a plastic bodied car. Plastic kitchen appliances can be molded in sumptuous shapes. How have we gotten to the point where we would be adverse to a plastic clad house, yet willing to accept a plastic sided house trying to look like a wood sided house? As described above plastic has a leg up over wood siding in many ways. Integral color, less costly, fast installation, light weight. These are positive characteristics that can build a compelling value statement in any product, and they are already well understood in the building industry. What we need to do is unleash plastic from its insecure identity, release it from its imitation of wood products and let it as a product set out to realize its full potential as a cladding material. Any siding has a multi faceted mission. It has to shed water and keep out wind driven rain. It has to be easy to install and interface well with adjacent building products like windows and doors. And lastly it has to make a nice and attractive appearance, one that leverages its inherent properties, and hence projects a character of authenticity.

In the building industry today we see a movement for sustainable building products. Some of these new materials involve the recycling of consumer plastic and put what would otherwise be a terrible waste product back into long term use. Plastic and plastic/wood composite deck boards are probably the most obvious product. The number of products on the market have increase rapidly as manufacturers from many related areas have rushed in to attempt to grab a piece of the rapidly expanding market. Clearly there is interest in utilizing recycled plastic content in new building materials. It seems the stage is set for one or more of these players to venture into a cladding product that also leverages this recycled material stream.

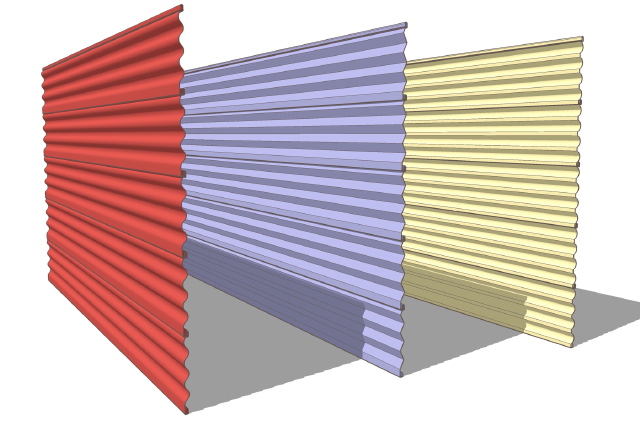

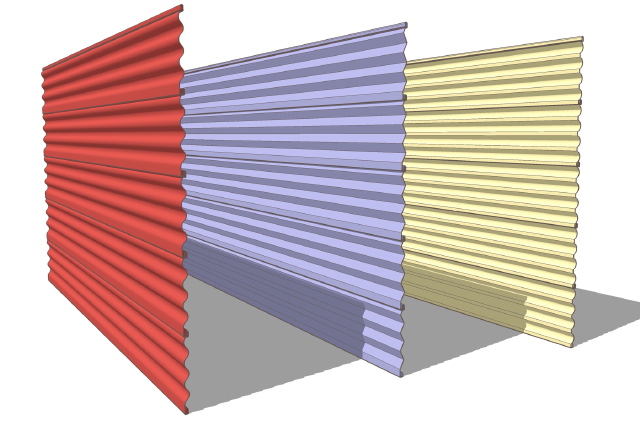

If one of these manufacturers were to make a cladding product, what would this "good vinyl siding" be like. Well first off it will need to find its own form. The profiles that have been based on copying wood lap siding profiles and molded shingle textures are compromises. They have leveraged plastic's ability to copy, but not is capacity to get the job of being siding done better. We need a panel with a corrugation pattern that will lend the panel stiffness it requires to eliminate sagging and rippling - flaws that project a thin and insubstantial characteristic to the material. These new corrugation patterns should be original and unique to the material, based on both the quantitative value of adding rigidity and the qualitative value of finding a pleasing and confident expression of its material character. We need more panels that work in a vertical orientation, as that is as easy to achieve with this material as is horizontal. Now that we are released from the precedent of horizontal lapped wood siding panels we can exploit new forms dedicated to a vertical orientation. Lastly we need new molded tile forms, akin to the process used to make faux wood shingles. New expressive forms can be created here, with effective water shedding joints that no longer need to be hidden behind the edges of our phony shingle facade. And these new siding products must be made to take advantage of our consumer waste stream, to repurpose plastic content from short term product cycles to long term building cycles, locking this waste into useful long life term utility.

Why is nobody moving to make this product? Is there no confidence in the american public to adopt an authentic product like this? Clearly the housing market would be slow to do so. Aside from our small modern movement most of the public would not understand a product like this. But it would find its place in light commercial construction where such phony schmony product as conventional vinyl siding is not always desired. If produced on a cost level with existing vinyl siding this new product could easily gain a foothold in light commercial construction, and then be readily available for new modern housing that is proud to wear an authentic expression of our times.

The candidates to manufacture this product are out there. Either one of the many players in existing vinyl siding, or one of the many new players in recycled deck boards and railing systems. There is a yawning opportunity there for a manufacturer with a vision.

So let this be a challenge to the industry - make it, they will come. Vet some idea, do some basic market research. Run some limited prototypes - I will help you find an application to test it. And you modernists out there - let your desires be known to these players. We want good, modern, affordable, effective cladding for our modern homes. We are waiting for you to serve us - who will be first?

Continue reading "What ever happened to all the Good Vinyl Siding?"

This Plat House has been modified to create 3 bedrooms, and adjust the roof overhangs for its siting facing roughly north. There have also been some other common sense changes for climate with the window sizes. The owners worked with local PEI architect Ross Macintosh to prepare a modified floor plan to suit their needs.

This Plat House has been modified to create 3 bedrooms, and adjust the roof overhangs for its siting facing roughly north. There have also been some other common sense changes for climate with the window sizes. The owners worked with local PEI architect Ross Macintosh to prepare a modified floor plan to suit their needs.

Inside we can see that they have built the house on a radiant heated slab - very nice. We are very happy to not only see more Plat Houses built, but also to see people fearlessly adapting them to their needs. We are looking forward to seeing more of the other Plat House projects underway in other parts of the country.

Inside we can see that they have built the house on a radiant heated slab - very nice. We are very happy to not only see more Plat Houses built, but also to see people fearlessly adapting them to their needs. We are looking forward to seeing more of the other Plat House projects underway in other parts of the country.

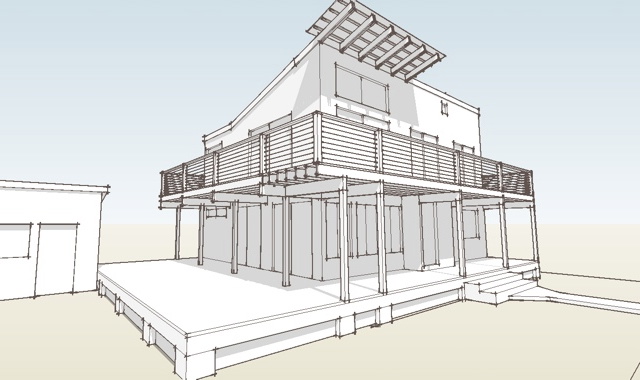

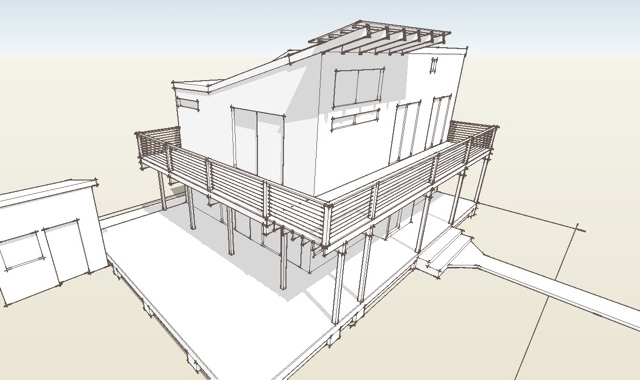

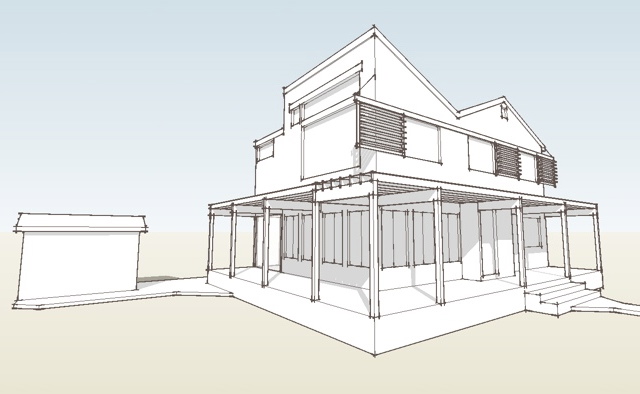

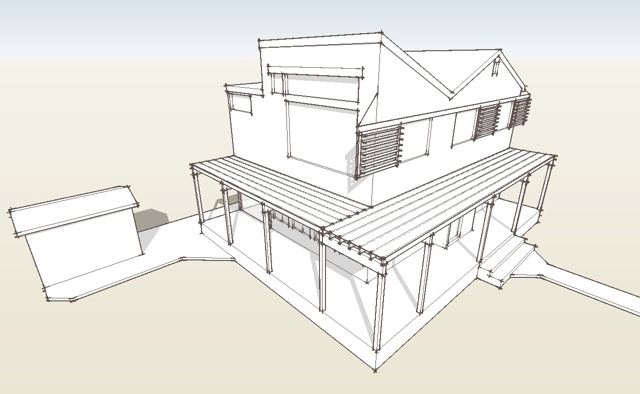

Now the existing roof line is hidden behind a new fascia, the roof slope of the new master bedroom turned to match up with the new fascia. The existing roof line still exists behind so we still manage to avoid reframing the existing roof, but the house turns a completely new facade to the street

Now the existing roof line is hidden behind a new fascia, the roof slope of the new master bedroom turned to match up with the new fascia. The existing roof line still exists behind so we still manage to avoid reframing the existing roof, but the house turns a completely new facade to the street

And yes, that is the existing attic vent worked into the new composition! This is still a rough massing model which will need further development.

And yes, that is the existing attic vent worked into the new composition! This is still a rough massing model which will need further development.

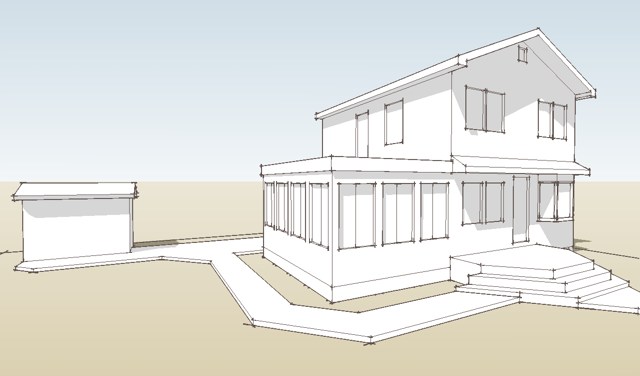

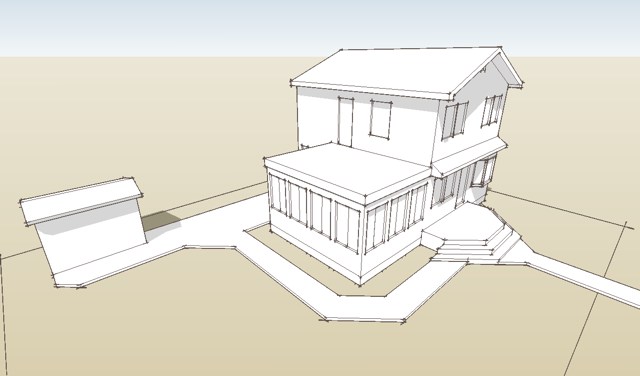

The idea here was to incorporate the existing roof line into a new and more dynamic profile. By removing the rake overhang and bringing the existing roof into a more purely geometric form we could bring out a more modern quality. This strategy also preserved the existing roof framing, and minimized our intervention, to extend what we could do with the budget.

The idea here was to incorporate the existing roof line into a new and more dynamic profile. By removing the rake overhang and bringing the existing roof into a more purely geometric form we could bring out a more modern quality. This strategy also preserved the existing roof framing, and minimized our intervention, to extend what we could do with the budget.

We also proposed a new wrap around porch, a characteristic of some of the older beach homes that date back to the late 1800s, early 1900s. It is a great mediating space between the street and the house, and a "hedge" that could easily become a balcony in scheme 2!

We also proposed a new wrap around porch, a characteristic of some of the older beach homes that date back to the late 1800s, early 1900s. It is a great mediating space between the street and the house, and a "hedge" that could easily become a balcony in scheme 2!

The owners wish to add a new master bedroom and bath to the second floor, and "re-invent" the exterior to make the house feel modern. They collected a wonderful range of images which they presented to me in the form of a collage. This has been a consistent reference point for me as the project has progressed. Some of the images were from their travels, others clipped from Dwell.

The first step in the design process after measuring the exiting conditions is to mockup the existing house in 3d to work with during design.

The owners wish to add a new master bedroom and bath to the second floor, and "re-invent" the exterior to make the house feel modern. They collected a wonderful range of images which they presented to me in the form of a collage. This has been a consistent reference point for me as the project has progressed. Some of the images were from their travels, others clipped from Dwell.

The first step in the design process after measuring the exiting conditions is to mockup the existing house in 3d to work with during design.

The small roof deck over the porch has a great view of the bay, yet the owners rarely use it because of its location.

The small roof deck over the porch has a great view of the bay, yet the owners rarely use it because of its location.

Budget is always a concern on projects like this so the question was how to re-invent while keeping the work limited. Thats it for now.

Budget is always a concern on projects like this so the question was how to re-invent while keeping the work limited. Thats it for now.