Letters from Sweden - another peak at the Swedish factory

My faithful correspondent Scott has forwarded a link to another interesting video showing the inside of a Finnish house factory, this time from manufacturer Lapponia, which is again typical of techniques used in Sweden. Again there is a mix of manual assembly, and big automation machines.

In some stills from the video we see the wall panels being laid out on the large "tables" and filled with what appears to be a very dense fiberglass batt insulation, not like the fluffy stuff we have in the US. In the clip you can see the insulation material being cut on a special table with a rolling blade.

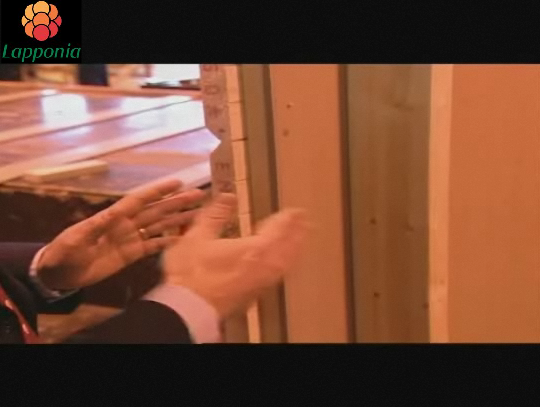

In this part of the film the company executive is explaining the construction of their wall panels. What we see here is a stud wall which looks to be closer to our 2x8 size than our 2x6s. That 2x8 stud wall is filled with the dense insulation, and then there is a second insulation layer on the outside of the wall, adding another 3" or so of what looks to be a rigid fiberglass panel. And finally on the outside of this is a heavy tongue and groove siding panel.

Its clear that the Swedes are achieving some very high performance houses using this construction. No SIPs, nothing unfamiliar to any US carpenter. They are just stepping it up. Up to 2x8 thick walls, filled with high density insulation. They are adding a second continuous insulations layer outside of that to fight the thermal bridging of the studs, and finishing it with a substantial and long lasting siding panel. This is something we could be doing here today.

Lapponia no longer has the factory video posted to their site, but their online catalog is here: Lapponia

Links to past entries in the Letters from Sweden Series:

Letters from Sweden - automation in the factory

Letters from Sweden - the foundation

Letters from Sweden - deliver and set

Letters from Sweden - plumbing the prefab

Letters from Sweden - wiring zen

Letters from Sweden - a windows tale

Letters from Sweden - panel building in Sweden vs the USA

Letters from Sweden - Europe is different, Sweden is not, sort of..

Letters from Sweden - land of modern, land of prefab

Letters from Sweden - conversations with an expatriate builder

Looks promising to me, yet there are quite a few barriers that need to be overcome (and we are, albeit slowly) for this system to work.

ReplyDeleteThe factory panel is something most builders haven't dealt with, but these shouldn't be problematic to set and manage. The typical framed and skinned wall on a McMansion isn't any easier to erect, in my estimation.

The construction, as you state, is remarkably similar to our own, and field modifications wouldn't be substantially different in technique, should they arise.

I'm thinking about some of the other obstacles that might come into play, here, such as industry inertia and the tooling costs associated with ramping up this type of production. These may just be perceptions by those involved, but let's face it, perceptions drive lots of stuff in this world.

I've really been enjoying your series of Swedish residential construction over that last, what, year? Please keep it coming whenever you get something to share.

One thing that Scott and I have seen making inroads in the USA are these plug together (no junction box) electrical connectors. This is key to being able to prewire these completed wall panels and connect them up quickly in the field during the set. The last thing you want is two trades dicing around when you are trying to drop panels and run.

ReplyDeleteI've also loved this series and hope it continues. I watched the video and I think he mentioned Rock Wool for insulation in there which many are using in Europe. It is available in the US, but I think it's mainly used in commercial applications.

ReplyDeleteAlso, in regards to electrical, why not run your outlets in the floors and use wireless switches for the walls? No need to run electric in exterior walls at all...