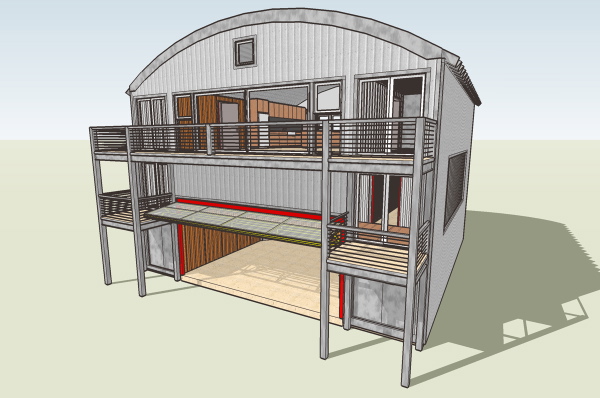

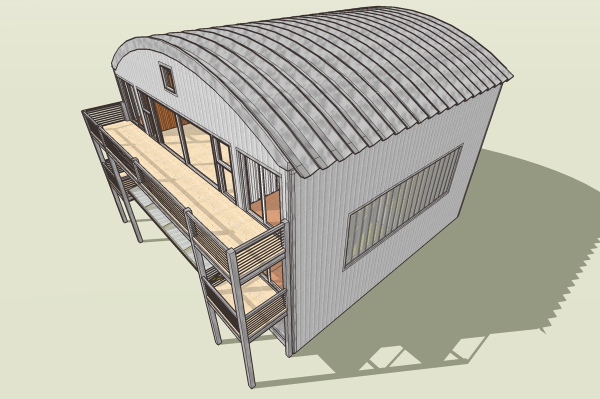

0859 Unger Studio - structure clad, with balconies

We are winding down on the conceptual design work for the Unger Studio today. Posted are current images of the state of the design.

The building will be clad, as its location requires it to be insulated. The owner is considering steel insulated sandwich panels similar to what we use on the EcoSteel projects.

The building will be clad, as its location requires it to be insulated. The owner is considering steel insulated sandwich panels similar to what we use on the EcoSteel projects.

The balconies are intended to be made from an industrial mezzanine system. The roof is a self supporting corrugated steel arch, a very economical structure. Normally its used to create inexpensive space under roof and would come all the way down to the slab in a quonset hut like fashion. We are experimenting with several appropriated building technologies in this project to try and keep the cost to a minimum. We will continue to report on how that plays out.

The balconies are intended to be made from an industrial mezzanine system. The roof is a self supporting corrugated steel arch, a very economical structure. Normally its used to create inexpensive space under roof and would come all the way down to the slab in a quonset hut like fashion. We are experimenting with several appropriated building technologies in this project to try and keep the cost to a minimum. We will continue to report on how that plays out.

Technorati Tags: container house, modern design, modern house, prefab house

Hi,

ReplyDeleteI have a question about the necessity of cladding. What about the ceramic coatings I have heard so much about on other container house projects. The stuff is supposed to have an R-17 value? Is that too low? Also in the views provided I do not see details for plumbing or electrical how is that handled (between containers, along walls, etc)?

Thanks

The simple answer Chuck is the project is in Michigan, and the winter weather is too extreme to rely on the insulating paint, at least until there is standardized test data supporting its performance in such conditions.

ReplyDeleteI'm very optimistic about the material. But at the same time it would be imprudent for me to recommend it to a client without reference to any standard. If it failed to perform it would be totally my fault, a risk that I, nor my client can take.

Hi Lavardera,

ReplyDeleteI agree totally, I do networks for clients and I take a similar approach when a technology is unproven. That brings up another question - which type of ISO container are you using in the design. Are you using the standard 7'10" (measured on inside) or the Hi Cube which is 8'9" x 40' containers.

Thanks

We are using both sizes Chuck.

ReplyDeleteHi Mr La Vardera,

ReplyDeleteI'm a great fan of your designs.

Any update on the Unger Studio. I would love to hear more about the insulation issues and interior construction issues (interior finishes, plumbing, electric.

Thanks,

RJ - Altanta

Hi RJ, basically we are in a holding pattern, waiting for credit to soften. Its a shame but this project came together as the economy came apart. Keep watching the blog - I'll pick up the story when it gets rolling again.

ReplyDeleteThere is an outside chance that something may change regarding the testing of the insulation by the time we are ready to build. If the data supports the painted insulation we may be able to reduce or eliminate the the insulation layer.

Interior finishes within the boxes will be exposed electric. Plumbing is concealed behind chase walls within the bathrooms. That is the strategy for now.

Greg,

ReplyDeleteHave been checking in on you and your work for a long time. Appreciate your efforts at being ecological and economical. Real homes/places for real people.

I live in Haiti and there's much talk about using ISBUs in the reconstruction of housing. In this tropical environment, would the ceramic paint suffice as insulation? We know that shading and ventilation are key things to have but there's so much hot sun! I really like the lines of the Unger Studio and your use of the arched metal roofing!

The company that introduced me to the ceramic paint was using it regularly for mobile facilities heading to desert environment. So clearly it has some use keeping out the heat from the sun. But these facilities were air conditioned for the computer equipment inside. I'm not too sure it will help much if there is no cooler interior to protect from the heat in the first place.

ReplyDeleteI would suggest that you first attempt to just paint them white - that will reflect as much heat as possible with any available off the shelf paint. Second I would attempt to create a shade structure of some kind - this can be a second roof built above the container boxes, or even as simple as a fabric shade or tent above them. They will stay a lot cooler if the direct sun is not on the box. See these examples:

http://www.akdn.org/slideshow.asp?Sid=3

http://www.designbuildbluff.org/text/project/img/img_dbb_2004_rosiejoe_01.jpg

http://www.designbuildbluff.org/text/project/dbb_2004_rosiejoe.php

The steel arches can be used to do this as well - they can span over a group of container dwellings and provide shade as well as protected outdoor space.

I see you are using the arches on your site already - excellent. Then you know of their economy and the ease of setting them up. They put a lot of space under roof for the money. And you are using the same strategy as I am in making your warehouse - create a larger space by grouping the container boxes around the perimeter. I know you don't have time to get an arch shipped, but that would be the perfect roof for your warehouse central space.

Theo - it seems you have workers with welding skills at your disposal. You might watch what this resourceful fellow in Texas is doing:

ReplyDeletehttp://thefieldlab.blogspot.com/2010/02/884-feet.html

He built his own roof trusses out of reinforcing bars. I know when reconstruction begins you'll have re-bar there this time. Keep it in mind, watch what he is doing.

Thanks for your input and observations. Will post another photo this afternoon of where we are at in our transformation. From what I've seen, the best by far seems to be the metal arched roof. It is self-supporting and probably cheaper than fabricating the roof structure and buying sheet metal. It's way better looking, too. You're right in saying that we don't have the time to purchase and have it shipped in for this project but we will for the next one.

ReplyDeleteYes - the arches are really a good product for all the reasons you state. When the time comes that you are going to attempt making the combination of container boxes and arch roof contact me and I will help you with some details - so you can request the proper connection clip from your arch supplier and have something for your welders to follow.

ReplyDelete