New Mexico EcoSteel House - house slab, observatory background

The floor slab for the house has been poured and we have received photos of the crew working on it. And today we will look at the third and final installment on the design process for the three structures we are building in New Mexico.

At the site you can see the slab pour going in and the crew working feverishly to place the concrete while its workability is right. The "landscape" of the floor slab consists of several stub ups for plumbing, and recessed areas for shower tile setting beds, and the most prominent feature is the recessed area for the media room.

At the site you can see the slab pour going in and the crew working feverishly to place the concrete while its workability is right. The "landscape" of the floor slab consists of several stub ups for plumbing, and recessed areas for shower tile setting beds, and the most prominent feature is the recessed area for the media room.

If you have not lived in a house with a slab on grade before, or have never seen one built it may come as a surprise that a good deal of work must happen before that goes down. There is just one chance to get it right, so things like plumbing drains which must go down are going to spend their life under a slab - inaccessible. That has to go in right the first time, and come up through the floor in exactly the right spot to correspond with the walls that will follow.

While they get ready for the arrival of the first steel parts we will look back at the most curious structure of the three - the observatory. The owner, an astronomy enthusiast, has had a very good quality instrument to work with, but always desired a fixed facility for an even more powerful instrument. This project was his opportunity to see that happen.

If you have not lived in a house with a slab on grade before, or have never seen one built it may come as a surprise that a good deal of work must happen before that goes down. There is just one chance to get it right, so things like plumbing drains which must go down are going to spend their life under a slab - inaccessible. That has to go in right the first time, and come up through the floor in exactly the right spot to correspond with the walls that will follow.

While they get ready for the arrival of the first steel parts we will look back at the most curious structure of the three - the observatory. The owner, an astronomy enthusiast, has had a very good quality instrument to work with, but always desired a fixed facility for an even more powerful instrument. This project was his opportunity to see that happen.

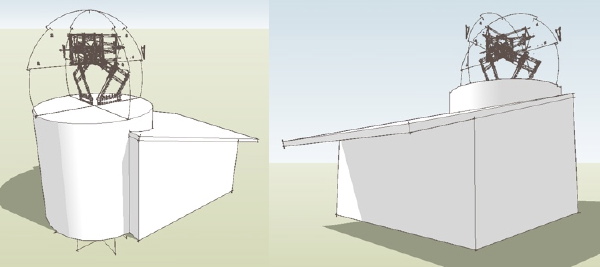

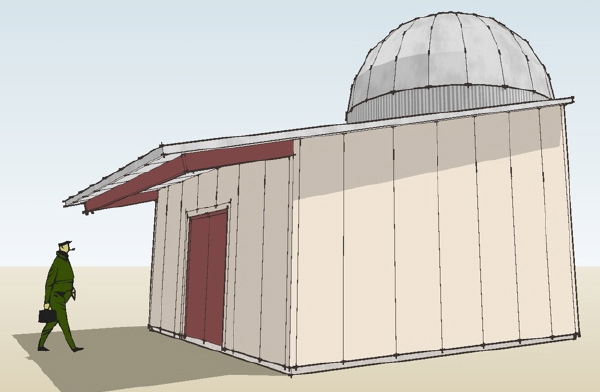

Working on this design was an education for us. I've always been interested in space and astronomy but never had a telescope. My brother and several friends have good telescopes but nothing that a consumer could not order from a catalog. This was different. The scope in this case is a precision instrument. It was going to be housed in a 16ft diameter dome with an operating aperture and motor driven base - just like the big boys. We did not have to design this - it is procured from a company that specializes in their fabrication. But we had to design up to it and support it. Adjacent to the dome is an equipment room. Here will reside computer equipment and tools and supplies to maintain the instrument. The computers control the tracking of the instrument, as well as manage image acquisition. You an use an eye-piece with the scope but the primary mode is a high res CCD capturing images and serving them to the operator who is remote. A web based interface allows for control as well as imaging so this is something that can be used where ever you have an internet connection. You do not need to be at the facility.

Working on this design was an education for us. I've always been interested in space and astronomy but never had a telescope. My brother and several friends have good telescopes but nothing that a consumer could not order from a catalog. This was different. The scope in this case is a precision instrument. It was going to be housed in a 16ft diameter dome with an operating aperture and motor driven base - just like the big boys. We did not have to design this - it is procured from a company that specializes in their fabrication. But we had to design up to it and support it. Adjacent to the dome is an equipment room. Here will reside computer equipment and tools and supplies to maintain the instrument. The computers control the tracking of the instrument, as well as manage image acquisition. You an use an eye-piece with the scope but the primary mode is a high res CCD capturing images and serving them to the operator who is remote. A web based interface allows for control as well as imaging so this is something that can be used where ever you have an internet connection. You do not need to be at the facility.

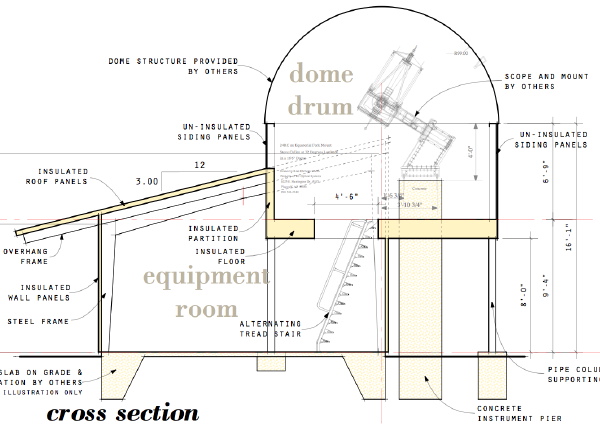

So we have these two parts - the equipment room which is conditioned for the electronics within. And the Dome which is not conditioned - it is intended to remain at ambient temperature so that when the dome is opened there is no thermal expansion or movement that would put the instrument out of calibration. We needed man access from the equipment room to the dome, as well as cargo access. So we have two hatches, one with a compact Lapeyre alternating tread stair, and the other clear for hoisting. The instrument lives within, elevated so that its pivot corresponds with the geometric center of the dome. It has its own foundation pillar which prevents any vibration of the building from transmitting into its mount.

So we have these two parts - the equipment room which is conditioned for the electronics within. And the Dome which is not conditioned - it is intended to remain at ambient temperature so that when the dome is opened there is no thermal expansion or movement that would put the instrument out of calibration. We needed man access from the equipment room to the dome, as well as cargo access. So we have two hatches, one with a compact Lapeyre alternating tread stair, and the other clear for hoisting. The instrument lives within, elevated so that its pivot corresponds with the geometric center of the dome. It has its own foundation pillar which prevents any vibration of the building from transmitting into its mount.

Once documented it underwent engineering and detailing in advance of its fabrication which is ongoing now.

Once documented it underwent engineering and detailing in advance of its fabrication which is ongoing now.

For the next update we should have the arrival of materials at the site.

For the next update we should have the arrival of materials at the site.

Doesn't the foundation for the telescope mount need to be slightly shallower or (preferably) deeper than the equipment building foundations in order to provide maximum vibration isolation?

ReplyDeleteI'm not an architect, but I have some knowledge of old mills (I live in one). The double-foundation system used to isolate vibration in water-powered grist mills usually involves two noticeably separate depths... such buildings were primarily built based on a purely empirical approach, nobody cared much about the "why" but they were extremely interested in "how to".

Maybe it doesn't matter in New Mexico, where the ground is presumably pretty dry.

That may very well be in a Mill where you have things in the building making constant vibrations. The concern here is more transient. I'm not sure if the foundation design will have the instrument pier go deeper. We typically don't design the foundations, and what you see in the section drawing here is only schematic.

ReplyDeleteThe HVAC compressor and ducting might be the worst vibration sources.

ReplyDeleteI've always wanted to get one of those old stainless or aluminum silo caps and convert it into an observatory. Thanks for posting this where everybody can see it!

I think the HVAC will probably be handled with a mini-split system. The compressor is outside and is not attached to the building. The indoor fan cabinet is very quiet and has minimal vibration.

ReplyDelete