Steel Case House mods - a detail study

A close look at the nature of the design modifications for this variation on the Steel Case House.

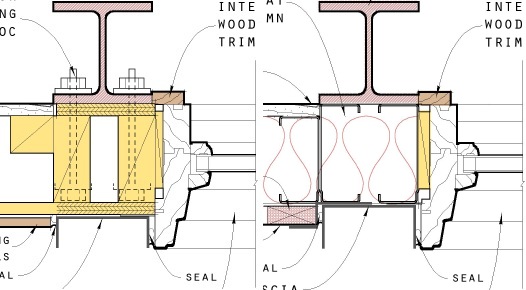

This is a comparison of details from the original 0357 Steel Case House, and the new Metal version. The detail on the left from the original shows conventional wood stud framing mounted over the structural steel frame. This is part of the logic of the house - once the steel frame is erected by the steel subcontractor the rest of the house can be finished with ordinary carpentry.

On the right in the new version we are dispensing with all things wood. Light gauge steel studs go directly over the structural steel frame, there is no plywood - corrugated metal siding is attached directly to the studs, and the strength of the siding takes the place of the plywood

On the right in the new version we are dispensing with all things wood. Light gauge steel studs go directly over the structural steel frame, there is no plywood - corrugated metal siding is attached directly to the studs, and the strength of the siding takes the place of the plywood

Technorati Tags: house plans, modern design, modern house, Steel Case House

Greg,

ReplyDeleteHow do you cope with the thermal transfer between the W member and the light gauge studs?

I am sure that this is a partial detail (don't want to give away your secrets) but it is something that is a big issue here in Chicago area.

Would love to hear your response can send to jbell_23 at yahoo dot com

As you can tell from the detail there is no thermal break. This is typical with many pre-engineered metal buildings, which is why the steel skinned insulated panels are used to clad them when they are insulated. I was in a bit of quandary over this. I did not want to use the insulated panel system in my stock plan, because that would create essentially the same kind of system used by EcoSteel. I did not want to create a plan product that was the same as their system so the compromise.

ReplyDeletenice

ReplyDelete