Today is the day - time to make the market grow up.

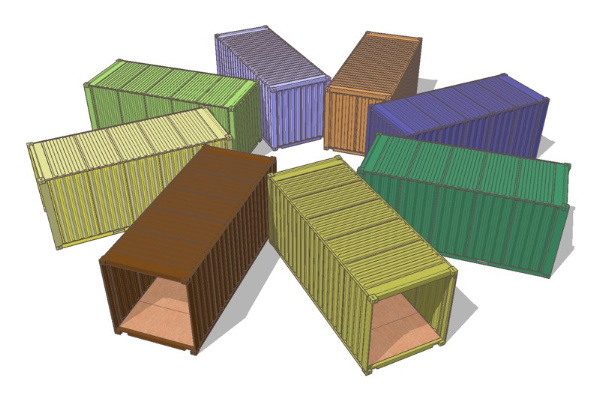

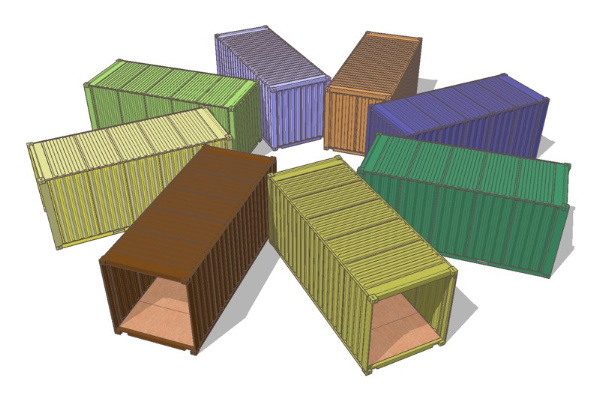

Next week I am going to be making a visit to a container maker/modifier in Tampa Florida, a division of TAW who creates specialty shelters based on the ISO standards for inter-modal transport, otherwise known commonly as shipping containers. You have to realize that there is a whole industry revolving around this, and its not run of the mill shipping containers that they are daily involved with. The military and other entities routinely deploy any variety of field shelters which get to where they are going by the usual channels of shipping cargo, and hence they conform to the standards set for handling shipping containers for dimensions, so they work with the universal stacking, and for strength, so that they can be handled in the usual manner. But aside from these concerns for "standards" their usual product could be something as sophisticated as an electronic field control center or as simple as a bunk room. So their routine business is fabricating inter-modal shelters for these varied purposes. But they also have a strong interest in seeing their business expand into day to day dwellings. Here is where the interests converge - there is a large group of modernists who are interested in using containers to create cool modern houses.

So we are meeting next week, for two reasons. First because I want to see first hand the work they do with these inter-modal shelters. Second because we want to talk about the big picture - how do we take this notion of building a house with containers out of this realm of fringe ideas, and set it on a course to being a mainstream option. We want container homes to "grow up."

Part of this is going to be establishing a common terminology. I have been talking to David Cross of TAW about this. Readers of Fabprefab will know David from his postings over there. The ideas I am going to pitch here are based on my talks with David and terms he has introduced.

Right now there is no way to talk about this except to say you are building a house of "shipping containers" which I can tell you first hand is not going to engender you to anybody. I witnessed a planning board vote to define a shipping container as a trailer in order to enable them to reject it as trailers were not allowed. Never mind that the object in question has no axles, wheels, or tires. We need to begin at a point which does not contain the prejudices built up from images of rusting hulks of shipping containers piled on top of freight vessels.

Generically what we are talking about is a modus of modular construction that uses heavy gauge steel, rather than the wood stick framing that is common in residential construction. Wow - why build something as light as a house with heavy gauge steel? There are very good reasons. Heavy gauge steel construction makes the modules immensely strong. The continuous wall footings that common houses require in order to prevent them from collapsing under their own weight are not necessary - heavy gauge steel modules can support themselves while spanning between supports at their four corners. In fact, to place them on continuous support is almost a squandering of their inherent strength, a waste of resources. But isn't it going to be expensive to overbuild like this, to make a house with such a strong structure? The answer is no. The resources are plentiful and cheap, and a sustainable factor of building with these is the fact that it represents a direct recycling of an otherwise neglected resource. That's because the raw materials for these houses are the cheap, pre-used ISO shipping containers accumulating in our ports thanks to our long standing trade imbalance.

So this is the foundation of this movement. The term is Heavy Gauge Modular construction, or HGM. I recommend you make this part of your vocabulary and start using it now if you ever want to see a "container home" in your future. Also, its time to start putting quotes around "container home", in your writing and your speech. Whenever you need to describe this to somebody make sure you always proceed the term with a phrase like "so called" or follow it with a phrase like "in concept". You get it - time to marginalize that term.

Now the next step in this is to talk about some specific characteristics of these Heavy Gauge Modules - HGMs. The modular industry is not standardized. Any readers of LiveModern and Fabprefab know that modules come in different widths depending on the factory space that builds them, the states that they will be moving through, the access to the site, and the special permits they require to transport. Sure we can build HGMs like this, and we will face the same restrictions to the market that the current Modular industry faces. Unh - Unh, no way, who needs that. We want a module that we can take anywhere, on almost any road, using standard trucks and trailers, no special permits required. While we're at it, lets make it possible to load it on a freight train, how about a cargo ship, lets make it work with the largest material handling infrastructure in the world. Lets make an HGM that conforms to the ISO standards for inter-modal transport. Lets call this HGM an Inter-modal Steel Building Unit, or ISBU - IBU for short.

Again, I advise you to adopt this language immediately. Today is the day we cross the threshold. Yesterday is the day of "container houses", Tomorrow is the day of HGM/IBU construction.

So now we are not talking about so called "container houses". We are talking about a new modular building method consisting of Heavy Gauge Modular construction utilizing Inter-modal Building Units. Coming to a planning board in your town. Soon.

Technorati Tags: modern design, modern house, prefab house, container house

Continue reading "So Called "Container Houses""

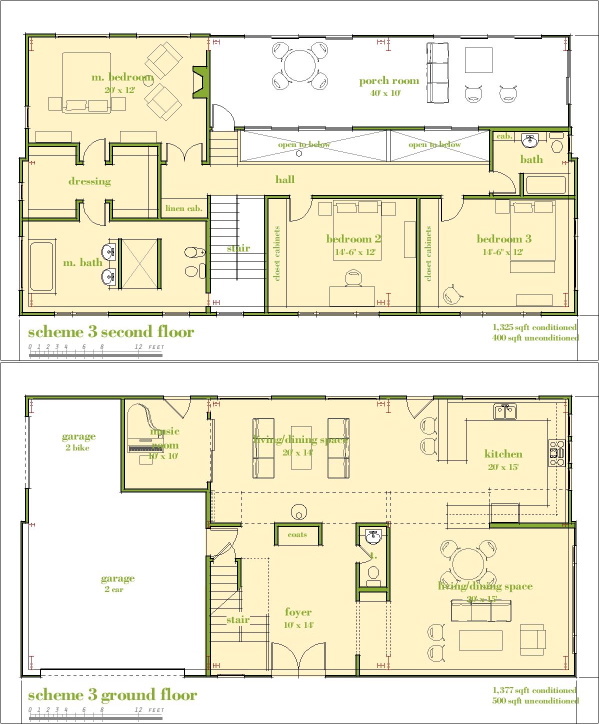

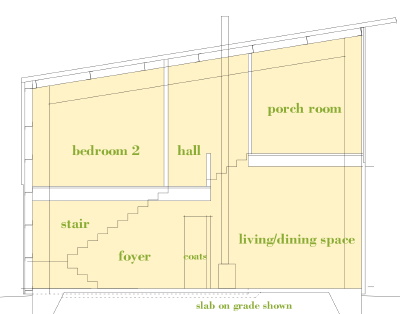

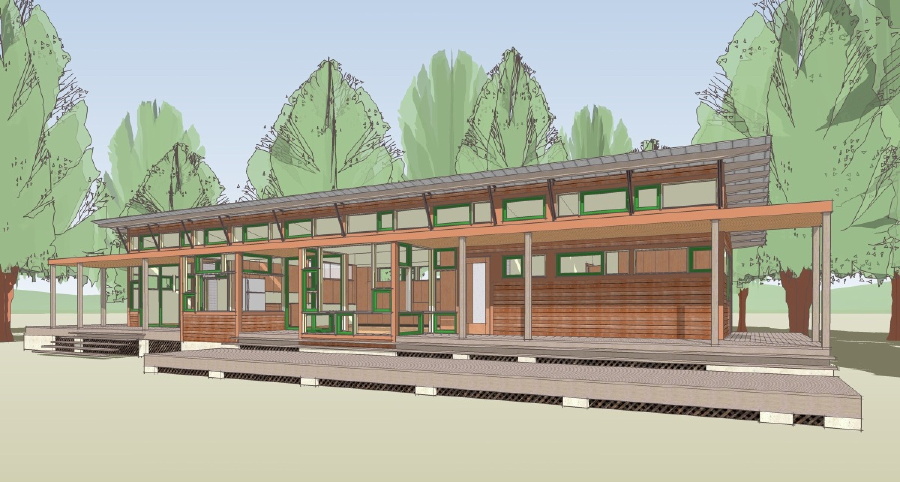

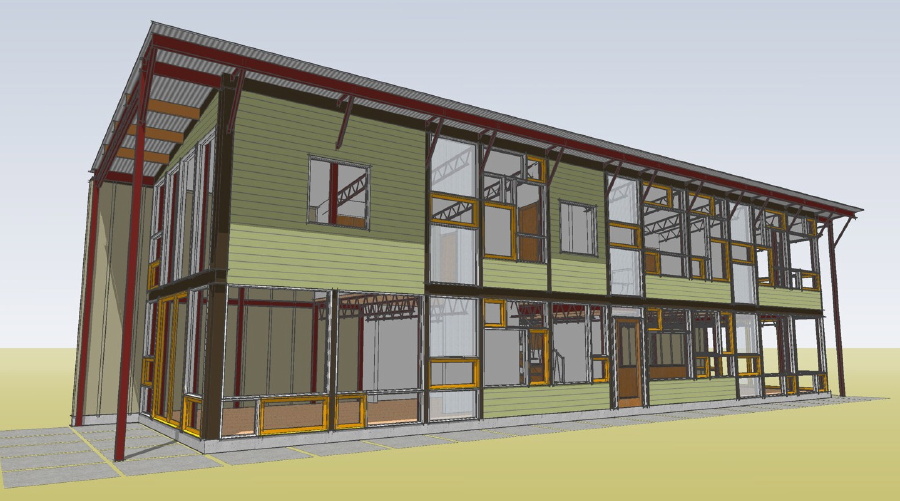

Upstairs the master bedroom remains a large suite with a master bathroom with potential to be very luxurious. Along with the other bedrooms these spaces form a buffer between the master bedroom and the public side of the house. Perhaps the most interesting part of this design is the porch room on the upper level. This is a modern 3 season room brought into the volume of the house. From here it can take in a great view or be up among the trees. An alternate living room it greatly expands the living space of the house and still leaves the areas below with a high ceiling. This very rough section shows the vertical relationship of these rooms.

Upstairs the master bedroom remains a large suite with a master bathroom with potential to be very luxurious. Along with the other bedrooms these spaces form a buffer between the master bedroom and the public side of the house. Perhaps the most interesting part of this design is the porch room on the upper level. This is a modern 3 season room brought into the volume of the house. From here it can take in a great view or be up among the trees. An alternate living room it greatly expands the living space of the house and still leaves the areas below with a high ceiling. This very rough section shows the vertical relationship of these rooms.

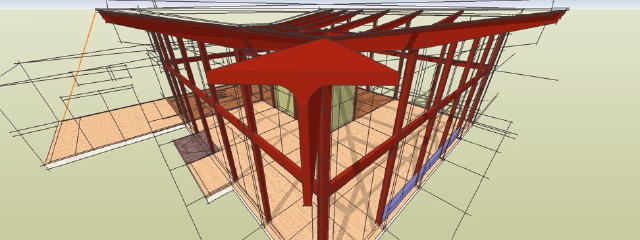

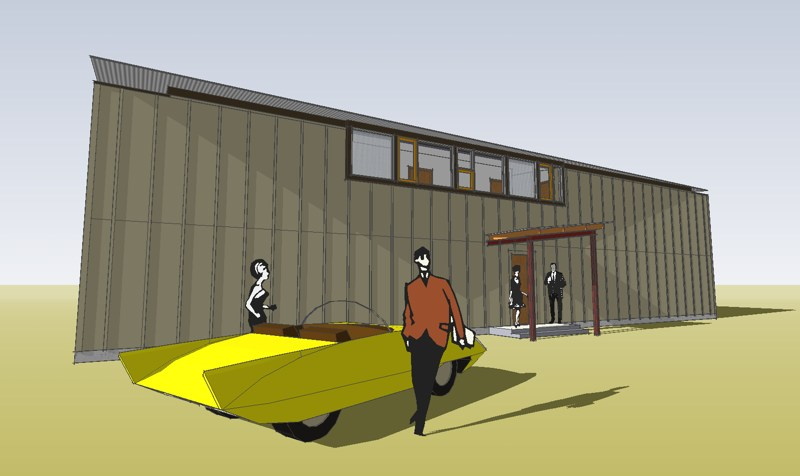

The ability to create voluminous spaces like this affordably lies with the EcoSteel building system.

The ability to create voluminous spaces like this affordably lies with the EcoSteel building system.

The floor plan is a variation on the original

The floor plan is a variation on the original

I like that. I can live with that.

I like that. I can live with that.

And the bad news is our prototype site has fallen through, or more specifically defeated by an unsympathetic HOA. Northern felt it was better to back off than to build bad will with neighbors so we are back to looking for a site. There are several strong leads with potential customers right now so we are not sure if the original prototype will be the first in the ground. We'll see.

And the bad news is our prototype site has fallen through, or more specifically defeated by an unsympathetic HOA. Northern felt it was better to back off than to build bad will with neighbors so we are back to looking for a site. There are several strong leads with potential customers right now so we are not sure if the original prototype will be the first in the ground. We'll see.

I have started a new

I have started a new