Letters from Sweden - A closer look at the Swedish wall

Today we're going to take a closer look at common wall construction in these Swedish factory houses we've been studying. The Swedes build their energy efficient homes using fairly ordinary materials that are not very different than what we use in the US. Ultimately we would like to propose a analogous wall system composed of materials widely available in the US - an American version of the Swedish wall. But first we have to look closer at what they are building.

Several of our earlier posts in the Letters from Sweden series touched on this. Most recently we looked at an automated assembly line, and through observing the assembly process we could see the various layers of the wall. Now we'll look closely at each layer using examples from a few factory web sites. Some Swedish factories market themselves as being green and some offer passive house options straight from the factory. What we will look at here is what I've found in my research to be very typical of Swedish house construction. A baseline if you wish of what the average wall in a Swedish house looks like.

First we must put this in perspective with a quick consideration of the average construction in the US. In the USA a comparitve average wall system would be 2x4 stud wall, with strand board and vinyl siding over tyvek on the outside, gypsum drywall on the inside, filled with R13 fiberglass batts. That's it. This wall is thin, cheap, and has poor energy performance. If you are in a colder US climate this may be offered with 2x6 studs and R19 insulation, or with a thin foam insulation layer in place of the strand board on the 2x4 wall. This is just enough to meet our meager energy code requirements. In the US vapor barriers which are supposed to keep the interior of our walls free of moisture typically come bound to the insulation batts. This makes for an open seam at every stud, and a hole where ever a switch or outlet is placed. As a result the wall is not air tight, not even close.

Ok, that is the typical in the US. Let's look at Sweden.

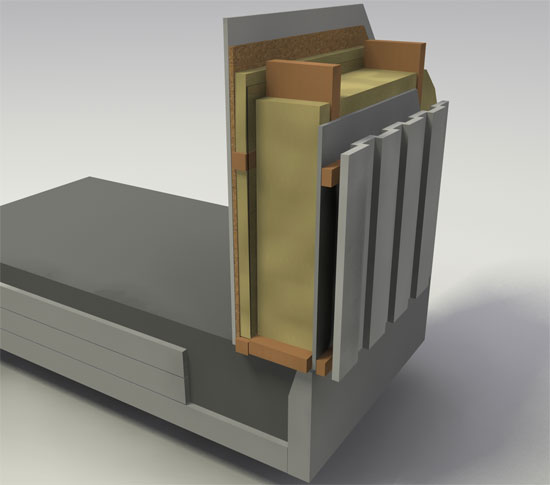

This wall construction diagram is from a factory called RejnäsVillan and is a good typical example of their practices. This diagram can be found on their site here.

Starting with the framing, they are using 195mmx47mm studs, which translates roughly to 7 3/4" deep, or a half inch deeper than our 2x8s. 200mm studs are also common, which come roughly to 8" deep. This stud space is completely filled with mineral wool insulation which is denser and has a higher R-value per inch than our typical R13 and R19 insulation.

Moving to the outside the stud wall is sometimes sheathed with a panel that is either a hardboard (like a masonite) or a gypsum board cladding. If they don't use a panel the wall is covered with an wind barrier similar to tyvek which stops air from penetrating the wall. This is in turn layered with horizontal furring, and often filled with mineral wool insulation approximately 47-50mm thick (not shown in this diagram), and then finally clad with thick solid wood siding boards.

Moving to the inside, directly in board of the studs the wall receives a heavy plastic vapor barrier that is applied in a continuous sheet. On top of that is a horizontal furring and this 47mm space filled with more mineral wool insulation. This is in turn clad with a particle board layer, or sometimes solid tongue and groove wood. And finally the interior gypsum panels. This deserves some explanation. The interior furring space serves a the place to run wires and plumbing, so there is never any electrical boxes making holes in the vapor barrier layer. This allows the house to be built air tight. This is analogous to the "disentanglement" layer that Bensonwood uses in their wall systems. The particle board layer is a convenience, to allow a homeowner to hang shelves, pictures, or cabinets anywhere without concern - there is always solid anchoring. The feeling is the additional material is cheap, and its presence adds greatly to quality, a logic I find difficult to fault.

Last of all this layering of furring strips and studs creates a thermal break that decreases the direct conduction of heat through the studs. This is something that Passive House proponents struggle with here in the US, leading many to opt for exterior foam layers to isolate the studs. The problem with this strategy is the foam is an inherent vapor barrier. In a heating climate that barrier wants to be on the inside. It can be done on the outside, but only at risk that with extreme temperature ranges the dew point could swing into the stud space and cause condensation, and then reduced insulation performance and mold hazard. I think the Swedish strategy is superior, and it is effective - Swedish factories use the same strategy in their Passive House wall systems.

So why do the Swedes build such quality walls, and the US not so much? Number one as a nation they were committed to reducing their energy consumption and they've been remarkably successful at that. We have not. Number two, their factory process allows them to build sophisticated walls like these efficiently. With our cheap walls factory building makes little difference. There is simply not enough value there to save very much. Its just as profitable to build on site when your walls are so cheap and simple. The Swedes however use the factory to make every house very high in quality, and very energy efficient. If we ever hope to do the same we will have to turn to a similar factory process.

Next we'll speculate on what a similar wall might look like built in the US.

Another excellent piece, sir.

ReplyDeleteI think the only thing that's going to get higher performance construction in general, and walls specifically, in this country is a serious shift in demand from the public, but, as I'm sure you realize, the vast majority of speculatively built homes are thrown together (guilty, as charged, I'll admit) without a care about how tight or well insulated they are.

It's not a matter of changing code either, as I've had to tear apart far too many items in my own home and seen all of the shortcuts and outright omissions that were somehow overlooked or greased through by a less than scrupulous inspector, if there even was one.

I'm currently burning wood in a retrofitted insert that is doing a decent job of keeping the temperature at a reasonable level inside. The furnace would never be able to keep up with the current conditions, and it's just downright bone-chilling when the wind picks up, which it does often out here in the plains. I'm considering a phased retrofit of the insulation in my home too, just so I can attain some level of comfort, green issues be damned!

Anyway, thanks again for the continuing work on the Swedish systems. They are informative, even for a fellow professional.

Things are much more clear in terms of climate in Sweden. Its roughly the same climate for the majority of the country, although they do have communities above the artic circle. So they can build to meet a generally uniform condition. Here in the states we have much more variety in climate, and the appropriate way to build varies by location. Unfortunately we don't respond with enough gusto to any of the climates we build in.

ReplyDeleteThanks for this excellent series on Swedish home building methods. I've just recently been looking at some off site builders in Germany (Hanse Haus, for example) and look forward to the day when I can walk into an office here in Canada and order my customized prefab passive house like they can in Europe.

ReplyDeleteMaybe once you've set something up with Bensonwood, you can see about exporting your houses north to Canada.

Fred, Bensonwood can serve Canada now if you are interested. Contact them and tell the I sent you.

ReplyDeleteOddly, I've personnaly found that most German homes (yes, new construction), tend to be of a clay tile type of load-bearing masonry, with traditional stucco over the masonry.

ReplyDeleteSeems terribly inefficient to me, but I've personally witnessed it throughout Baden-Wurttemberg as well as Bavaria. These same houses are sometimes fully festooned with solar panels on the roof. Again, odd when the weather seems to border on rainy to severe cold and windy under overcast skies.

Yes, the Germans and the Swedes are definitely different cultures. That manifests itself in a variety of ways as far as house building is concerned. Germany has had a big push for solar energy, so there is some state sponsored support behind the widespread solar panels.

ReplyDeleteHow deep is the interior furring space ? It doesn't look deep enough to run plumbing... espec. waste pipes or ventilation.

ReplyDeleteThanks for sharing your info with those of us who are looking for a much better way to build here in the U.S. that is still reasonable and affordable.

Any cost comparison info on Swedish wall to 2x6 cellulose insul, exterior thermal barrier U.S. high energy efficiency wall ?

Is the cost of Swedish wall balanced by the mass production of the building "unit" ?

Great article and info.

In the Swedish wall the furring space is typically 50mm. And no, it is not big enough for a drain pipe. But I think Swedish houses tend to keep drain piping within interior walls. For comparisions to 2x6 walls, no, I don't have that but recommend you read my page about American versions of these wall assemblies - see link to USA New Wall at the top of the right side-bar.

ReplyDeleteWe have success in selling mineral wool board as an alternative to foam board exterior continuous insulation. Two questions: First, if I understand correctly, the thermal break in this assembly is to the inside. Doesn't this run counter to the idea of moving the dew point as far to the outside as possible? Second, doesn't running the furring strips horizontal pose drainage issues for bulk water?

ReplyDeleteMark,

Delete#1 the above assembly has two thermal breaks - first from the exterior insulation layer, and second from the insulated wiring chase at the interior.

As far as “the idea of moving the dew point as far to the outside as possible”. I’m not sure who’s idea that is, but for this assembly with an interior side vapor control sheet it really does not matter where the dew point falls - it will be outside the vapor sheet, and will never encounter high RH interior air. The exterior side of this assembly is completely vapor open, and so any wetting will dry to the exterior.

#2 no danger of bulk water not draining. The staggered vertical board siding leaves regular open spaces on the outside of the furring strip which would drain water if it occurred. However I have seen other Swedish assemblies where the first put up a vertical furring strip, and then a horizontal strip leaving a gap behind.

There is variety in the assemblies from different manufacturers - this is just a good representation of the typical