Raising our standard of care

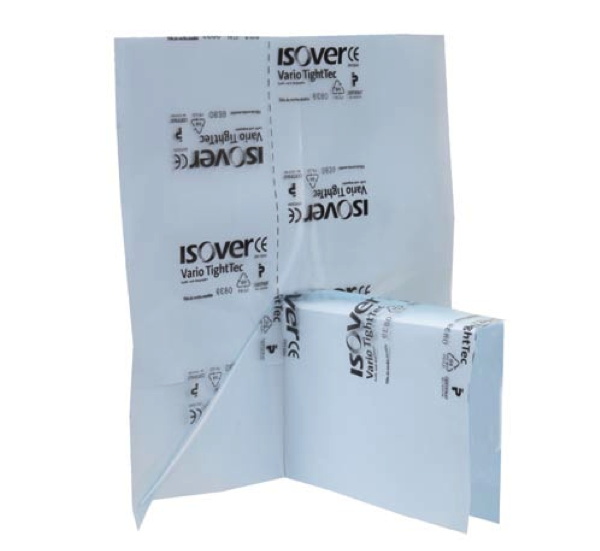

One of the foundations of how the Swedes build houses is the air tight barrier created at the vapor retarder/barrier plane of the wall. There is a movement about in the US to push that air barrier to the exterior of the wall, and the vapor retarder with it which raises a whole host of other problems. One of the issues is that its well known that its nearly impossible to seal an air barrier around the floor joists of a two story house. Well how do the Swedes do it? Simple, they use this:

Doh! Why didn't we think of that? Why not is a good question. Its because our standard of care is too low. Builders everywhere in the US use fiberglass batts with asphalt impregnated craft paper as their vapor retarder. This is trimmed loosely around obstructions and never achieves an air-tight barrier. Now that more builders are thinking about this I see decent air barriers installed, but the space between joists - spray foam is recommended. Another subcontractor, another process, another reason for a builder not to bother. So that's why the Swedes have these clever folded vapor barrier sheets - so they can quickly wrap and tape off a penetration by a floor joist or beam. They don't need a special insulation for between the joists or new trades or subcontractors.

When we designed the USA New Wall we deliberately avoided this issue by bearing floor joists on a ledger in the wiring chase, so that the air/vapor barrier could run up the wall uninterrupted. Why? Because we can't go out an buy these neatly folded barrier sheets here in the US, because nobody demands them, because our standard of care is so poor. But many Swedish factories use these with conventional platform framing despite the additional thermal bridges. We like the USA New Wall approach better, but remember, its all about doing better - not paralyzing yourself because you are not doing the very best.

We have a long way to go here. How far? Here is an envelope that arrived in my office today. This is a standard parcel envelope provided by the Swedish Post Office. Not only is the envelope remarkably sturdy, but its beautiful in function as well as simply its aesthetic. This is the standard of care the Swedes bestow on a postal envelope.

Not only that, they make these envelopes in Sweden. Not China, not Mexico. In a country the size of California, with the population of New Jersey, they have an industry - it may be just a couple of dozen people - but they make their own freaking envelopes, and damn beautiful ones at that.

Meanwhile over here we are trying to stave off the country becoming one big Walmart. We need to do better, and we need to raise our expectations. Call to "Buy American" are not enough, not when manufacturers are not willing to "Make American". If we want to pinch our middle class for the benefit of our top earners, we'll never raise our standard of care. We'll never make a good postal envelope if people are just trying to survive, and we'll certainly never make energy efficient houses that the middle class can afford.

Here lies the big opportunity, for smart builders to start supplying product to this gaping hole where there are no products to meet demand. I'm here ready to help builders implement the USA New Wall and Swedish Platform Framing in their work. Who will take me up on it?

that's brilliantly simple looking...

ReplyDeleteDo they fold the sheet on site, or it comes prefolded ready to go?

btw, the follow up on the envelope and our manufacturing industry (or lack therefor it seems), SPOT ON!

Rob, I think they buy these folded pieces pre-folded for this purpose, however I think its a third party company that does the folding part using the vapor barrier sheet from Isover. Isover makes the sheet material, but not the pre-folded product, so somebody else makes the folded "accessory" as an added value product, and again something made "at home". Isover is sort of like a Certainteed entity in Europe, a big insulation maker.

ReplyDeleteSo the wall panels come from the factory with the vapor barrier already installed, and a flap extending past the top that you can tape to. When the joists are set these folded pieces can go around the joists and everything taped tight before the deck goes down. I think in practice the deck is already in place in the center of the room, and a margin is left around the perimeter to complete this work, run wiring, and radiant heating tubes before the last of the deck goes down.

good god that sounds BRILLIANT!

ReplyDeleteI'd love to know how much that company makes just to fold these, or if the contractor justifies doing it themselves. VERY interesting product and approach.

so right now here in US what is the best way to seal vapor barrier around tjis on two story structure? i am thinking polyisocyanurate boards cut to fit between joists and than just foam primeter of each board, and bring wall poly and seal against them. sounds quite time consuming though. i assume my 1st floor ceiling doesnt need vapor barrier since both floors are heated.

ReplyDeleteTJI's are the worst to seal around, because they have twice as many corners as an ordinary joist. I don't have any great advice for you here. Lots of tape, lots of patience. Spend some time looking at the Swedish Platform Framing article linked at the top of the right sidebar. The best strategy is keeping the joist ends in-board of the vapor retarder.

ReplyDeletethanks, that article is very useful for me right now. also in your exterior wall design referred as best, where does the condensation occur? i am interested in this as i might use it. from what i remember from school the best way to avoid condensation in wall was to place layer with highest R-value closest to exterior. i remember placing rigid on exterior side of cavity alone would push condensation outside and than when adding batts it was really counter productive as it would pull condensation plane inside the wall cavity. not exactly sure if i remember this correct. but seeing another high R-value layer on interior side just got me interested how it works.

ReplyDeleteWhere does the condensation occur? If the wall is performing correctly there is no condensation. The vapor retarder prevents the moist air from reaching the part of the wall that is cold enough to allow condensation.

ReplyDelete